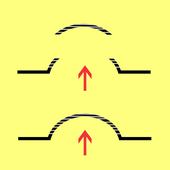

Questa procedura innesca proprio il possibile distacco di uno strato all'altro, quando l'elemento é sottoposto ad una forte sollecitazione, come

una possibile trazione.

Un caso tipico: un elemento sottoposto ad un pressione idraulica.

William Yerazunis, un ricercatore del gruppo Mitsubishi Electric Research Labs (MERL)ha realizzato e provato una procedura di stampa realizzata incrociando gli

strati fra di loro.

La tavola sulla quale viene realizzato l'oggetto si sposta liberamente in direzioni programmate:

In questo modo di puo' realizzare una speie di "tessuto" con strati realizzati come una trama ed un ordito in un tessuto.

Il movimento della tavola puo' essere programmato anche per realizzare delle "curve" con strati concavi oppure convessi a seconda della necessità di

resistenza richiesta all'oggetto.

Questa procedura realizzativa richiede una complessa programmazione iniziale ma poi si ottengono risultati di grande interesse.

I primi esperimento hanno dimostrato come la resistenza meccanica a sollecitazioni lineari sia incrementata di quasi tre volte.

Questa tecnica dovrebbe permettere anche la realizazione di parti strutturali - dello stesso elemento - come rinforzi di bordo o nervature interne, in grado di

conferire una maggiore capacità di assorbimento e smorzamento delle vibrazioni.

La stessa tecnica dovrebbe dare ottimi risultati su elementi sottoposti alle sollecitazioni a fatica.

This method of Additive Manufacturing is proving to have some pretty useful strengths, including strength in the literal sense.

William Yerazunis, Ph.D., Senior Principal Research Scientist of Mitsubishi Electric Research Labs (MERL) has been experimenting

with this technology to look at making 3D printed parts stronger.

The aim for this project was to make printed parts strong in the areas where they need strength.

Conventional 3D printing creates objects in horizontal layers, and these layer create weak points.

If there is a force pushing in the opposite direction of the direction these layers have been printed, such as up and through a part,

it forces these layers apart.

3d print break

Printing at various directions, named 5D printing, is said to make printed parts three

to five times stronger than conventional 3D printed parts.

The print plate moves as well as the printer head as it prints,

so the printing path follows the shape of the part rather than being printed in a straight layer.

Testing

To test this, Yerazunis printed two parts using the same CAD model, same plastic from the same spool,

and on the same machine.

The only difference between the two were that one was printed conventionally,

whilst the other was printed using the 5 axis printing technique, which ended up using 25% plastic.

The two parts were then each put under an increasing amount of pressure from the underside, and the point at which they broke was recorded.

The conventionally 3D printed part broke at 0.1 mega pascals, whereas the 5D printed parts broke at 3.7 mega pascals.

This is a very significant result, and could mean this alternate method of 3D printing

could be incredibly useful in various applications where the strength of parts is an important feature.

It could also mean that these applications could save material and therefore material costs whilst benefiting from a

great increase in strength in comparison to conventional 3D printing techniques.

However, this method requires more thought and preparation before printing.

This test was also only run on plastic parts, so it is yet to be said if this is the same for other print materials.

Yerazunis says, “5D printing does require a lot of analysis and it does require knowing how the part will be used.

But when you can make a part that’s five times stronger, that really changes how you think about 3D printed parts.”

( Giorgio Comerio )